10 reasons for choosing GW

1, GW certified by ISO14001:2004/Intertek & ISO/TS 16949:2009/SGS.

2, Designing – verifying – Process Technology - Production - Inspection can be executed completely in house.

3, Over 10 patent toolings & checking fixtures to ensure the efficient & reliability of the production.

4, The casting pieces size range : 5g ~ 10000g.

Annual output(Al.): 8000T.

Annual output(Mg.): 40 million Pieces.

5, GW has professional mold team + professional machine for mold tooling creation & maintenance as well as Anycasting conducted for mold flow analysis.

6, All powerful multi facilities are GW’s strong backup.

Central Furnace: 4 sets.

Die Casting Machine 135T ~ 2000T: over 40sets.

which equipped with auto feeding, spraying, loading & capturing manipulator, Safety, Efficient & Stable.

7, GW owns over 300 sets of Hi-precision various CNC machines, all requirements can be fully fulfilled.

8, Advanced Chemical Film Forming production lines

Ensure the Anti-corrosion, Anti-oxidant and the good contact of the products urface.

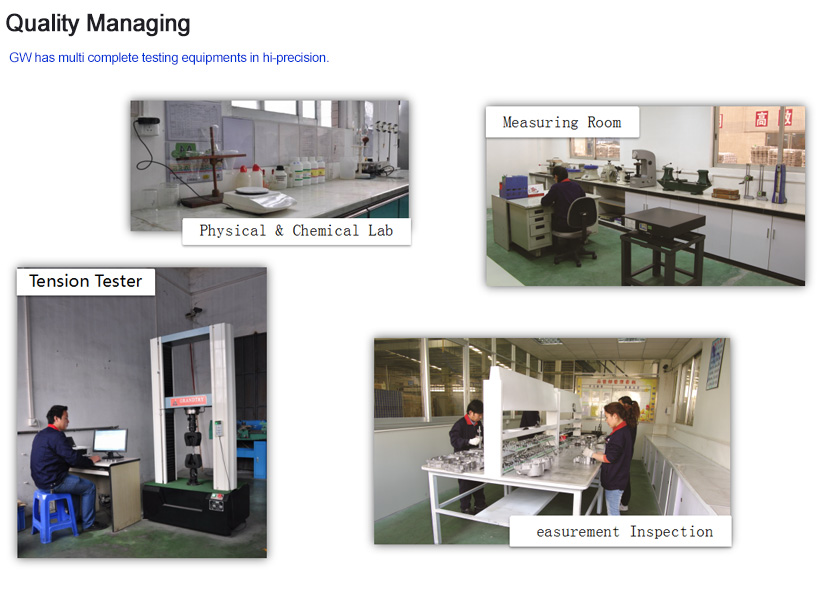

9, GW has multi complete testing equipments in hi-precision.

10, Rejected rate: </= 100PPM, this makes us proud.

Copyright © 2016 Jiangmen Gewei Precision Machinery Co.,Ltd All Rights Reserved.

江門(mén)網(wǎng)站建設(shè):新一代科技 Aluminum alloy casting factory | Magnesium alloy casting factory | Zinc alloy casting factory | Magnesium alloy die casting products | Magnesium alloy die casting process | IT & Telecommunication die casting parts | Motocycles die casting parts | Kitchen die casting parts